|

Wuhan Solar Sunrise Photoelectric technology Co., LtdChina Professional Solar Cell Tester, Solar Module Tester, EL Tester manufacturer |

|

||||||

Online EL Tester

Product Description:

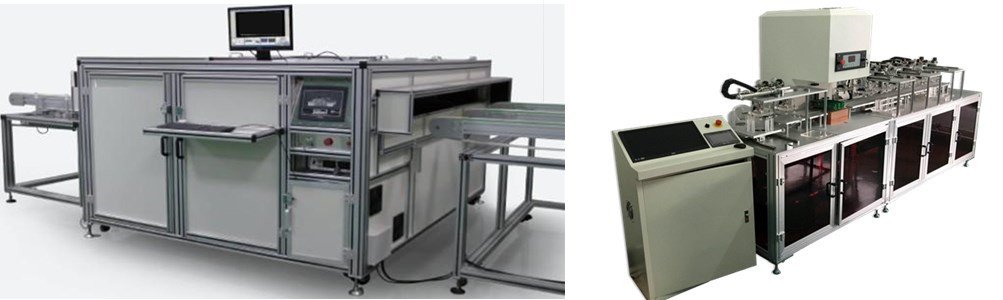

Solar module Auto Online EL Tester: EL-1600

Introduction:

The working principle of EL Tester is to detect internal defect of solar modules by electroluminescence.

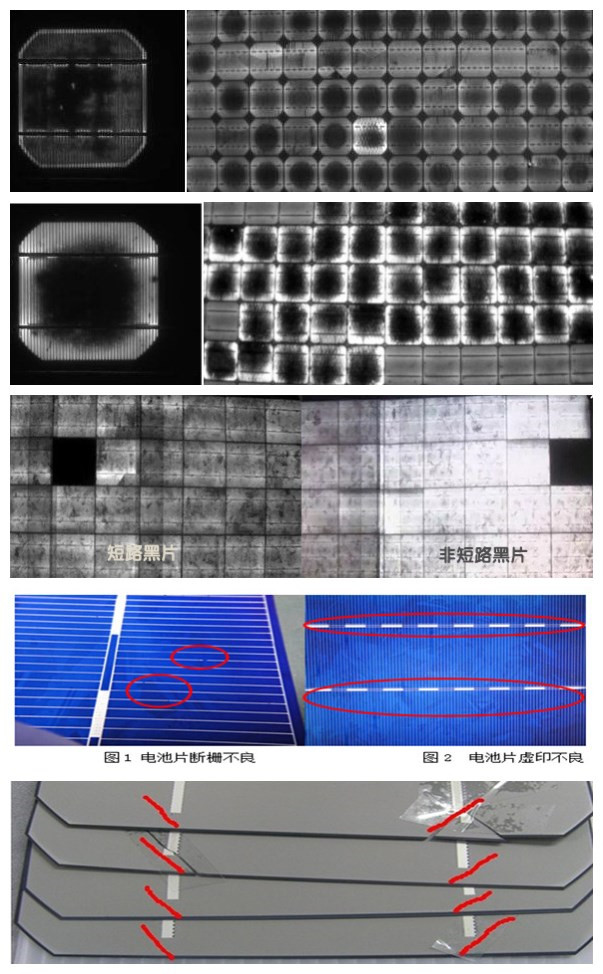

Test and inspect the micro-crack,breakage,broken fingers of the cells and pseudo-soldering of the modules,also applicable to check or find the mismatch of the cells or stringers with different power rating.

Features:

1. Bigger and clearer Images, so that it is very easy to find all solar modules defect.

2. High automation with auto Picture&storage, automatic recognition for serial number.

3. High detection efficiency: advanced imaging system with optimization design to realize single module detecting time within 50 seconds.

4. System of high stability to ensure 100% electrified rate for solar modules.

5. System operation panel and software are very easy and convenient to use.

6. Powerful auxiliary functions: This equipment can be connected to solar modules assembly line and implement interactive information. Other customized functions can be added by our developing group upon customers’ requirements.

Applications:

Test and inspect the micro-crack,breakage,fragment of the cells and pseudo-soldering of the modules.

Check and find the mismatch of the cells or strings with different power rating.

Technical Specifications:

|

Solar Module EL Tester

|

Auto Online EL-1600

|

|

Detecting Module Type

|

Solar cell modules(Mono-Si and Poly-Si)

|

|

Detecting Module Size

|

Max : 2000mmx1200mm

|

|

Max. Resolution

|

4928H*3264V

|

|

Pixel rate

|

4.8μm*4.8μm

|

|

SNR

|

>56dB

|

|

Dynamic Range

|

72dB

|

|

Exposure Time

|

1/250s-30s

|

|

Imaging Time

|

6-8 seconds

|

|

Test Period

|

8-12 seconds

|

|

Sensor Type

|

Sony from Japan

|

|

0~30A / 0~100V

|

|

|

Power Supply

|

AC220V/50HZ/1KVA

|

|

Work Environment

|

’+15℃~+40℃ / 10~75﹪(Humidity)

|

|

Storage Environment

|

’+5℃~+40℃ / 5~85﹪(Humidity)

|

|

Image noise

|

No

|

|

Management Software

|

English interface, auto save&statistics, query&print for images

|

|

Detecting Content

|

Technological source, material defect, micro-crack, fragment, broken fence, pseudo-soldering, poor efficiency.

|

|

Degree of Automation

|

Cover plate controlled by air cylinder, solar modules manual feeding, manual electrify,manual scan bar code/serial number

|

|

Dimension

|

2350mmx1600mmx1020mm

|

EL testing samples: